I frequently encounter a crisis of identity when I try to describe myself with certain terminology: designer, craftsman, artist—they all seem alternately applicable to the nature of my career. I know this is mostly a self-inflicted conundrum. It’s not as though anyone insists that I define my work in narrow, exclusive or absolute terms. I hope that in time I will simply care less, but at this moment it’s something I mull over often in an effort understand and define my goals and values as a maker of things. I don’t actually believe there are divisions between these terms or that they are fixed in relation to one and other, but each word has the power to connote a different emphasis on how one is engaged in a creative act.

A defining aspect of my work (one that I attribute to my craft training) is that in addition to being concerned with the aesthetics of an object, I am equally attendant to the“beauty” of process. I mean this in the same way one might describe a beautiful equation or piece of computer code—not really an aesthetic experience so much the idea that I have done something in the best possible way. In my case I am speaking about a combination of speed, economy, cleverness and pleasantness of actions that combine to create grace in process. This may not have an visual impact on the object but is an avenue for engagement. I also believe that a beautiful process tends to generate objects that have a clear, un-muddied quality, regardless of the particular aesthetic.

Most of my projects leave limited room for deeply exploring the beauty of process. Though it is on my mind all the time, I am usually making a single, one-off piece, and there’s no opportunity to go back and redo steps unless I have really screwed up. However, once in a while, I take on a project in which my goal is to explore and refine my sequence of actions. This simple pewter cup is one such project. I have made it a few dozen times over the last three years in order to home in on a process that works within my limited tooling and design parameters, which are that it must be a versatile size, impart the perceived value of a hand-formed metal cup, be well-crafted and reasonably priced.

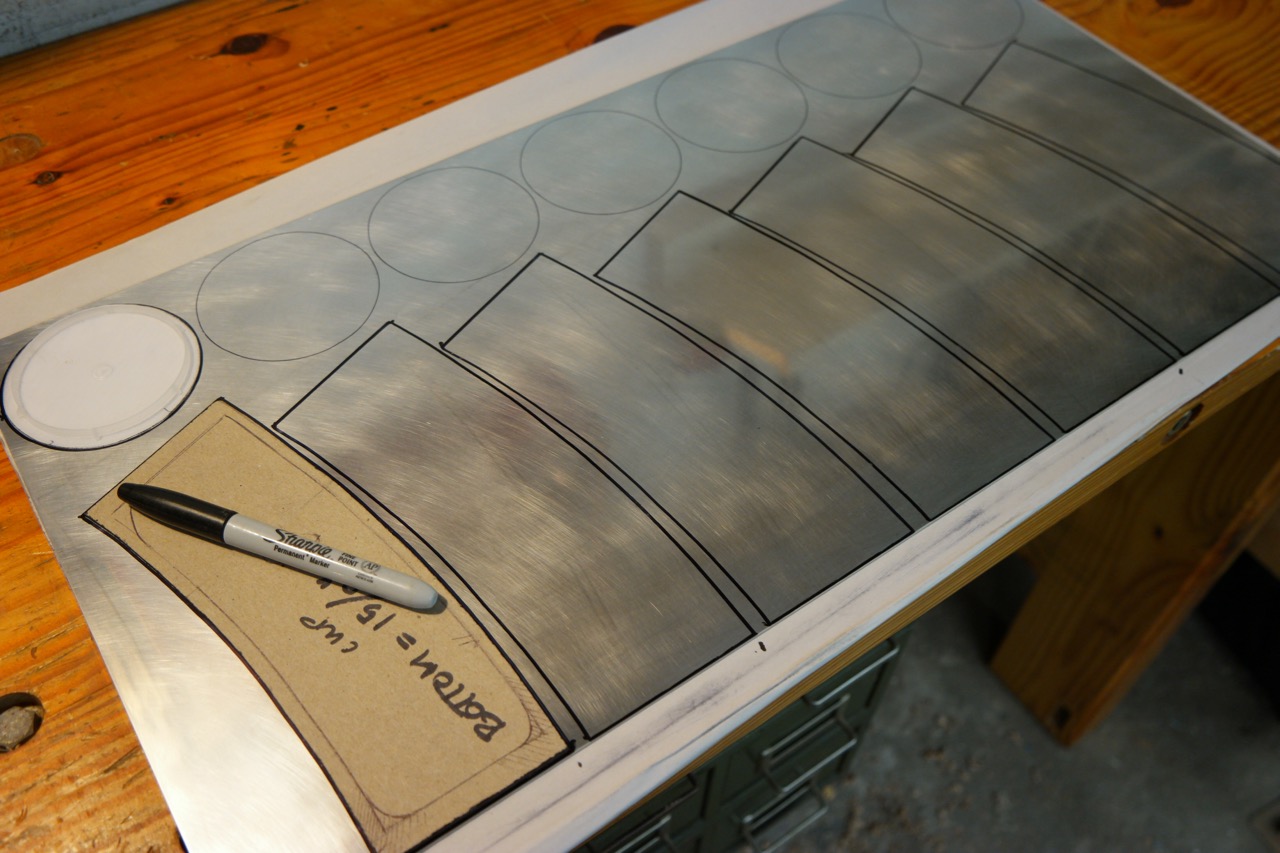

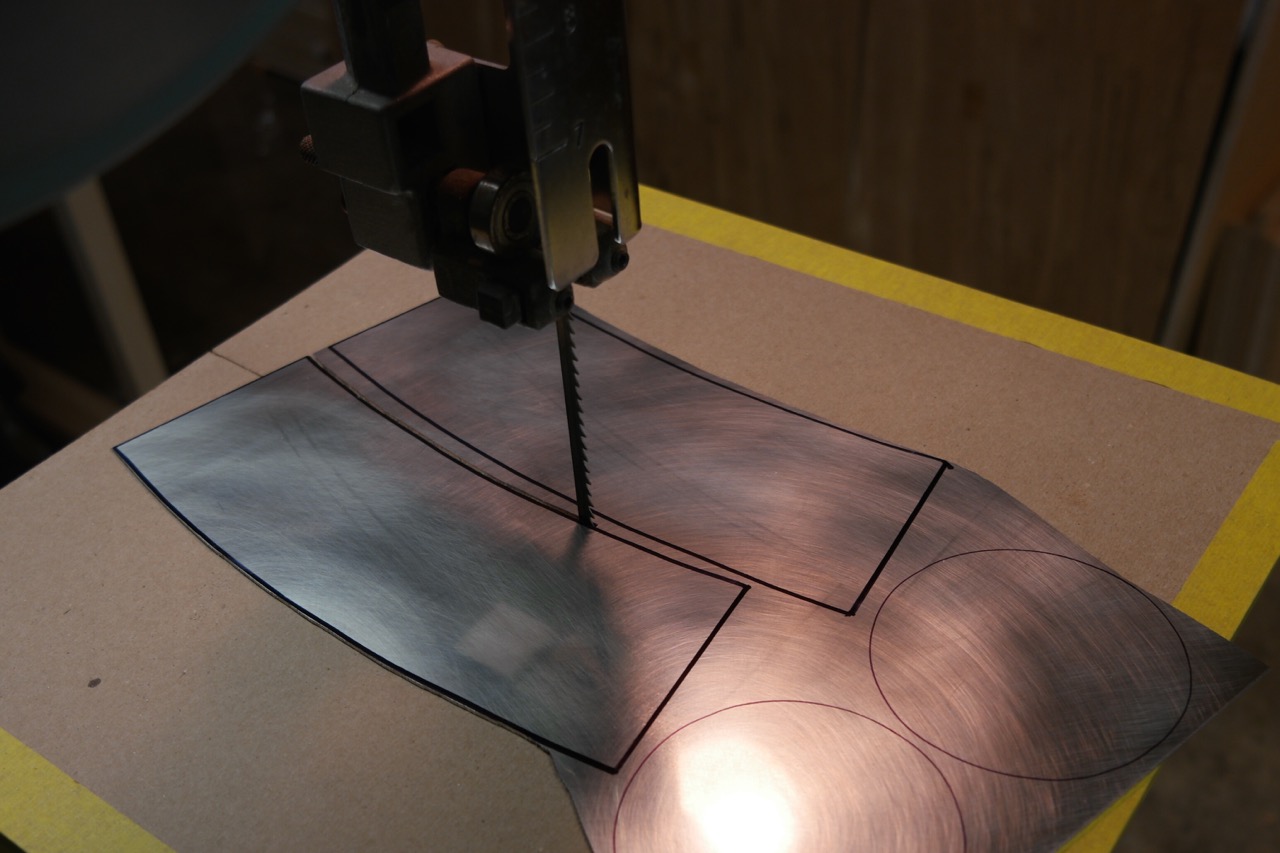

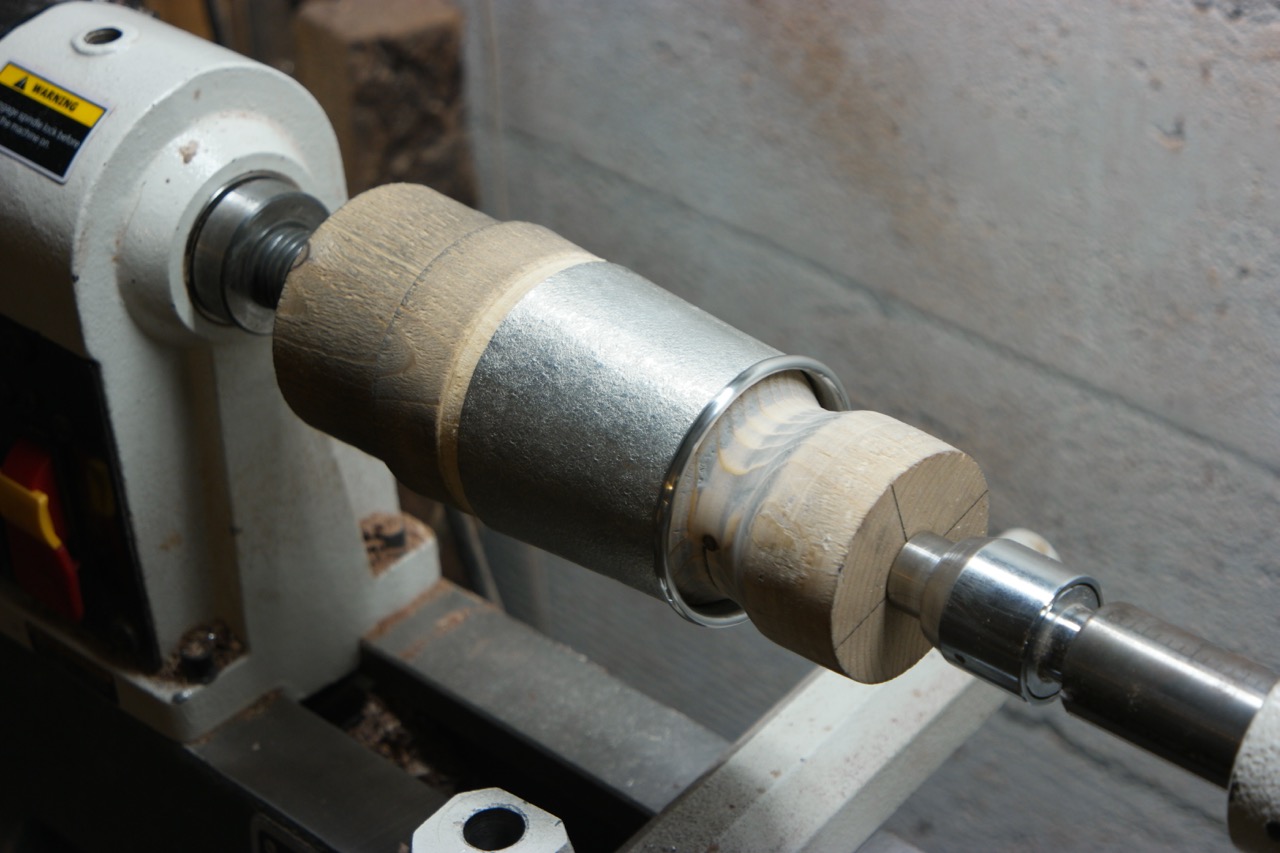

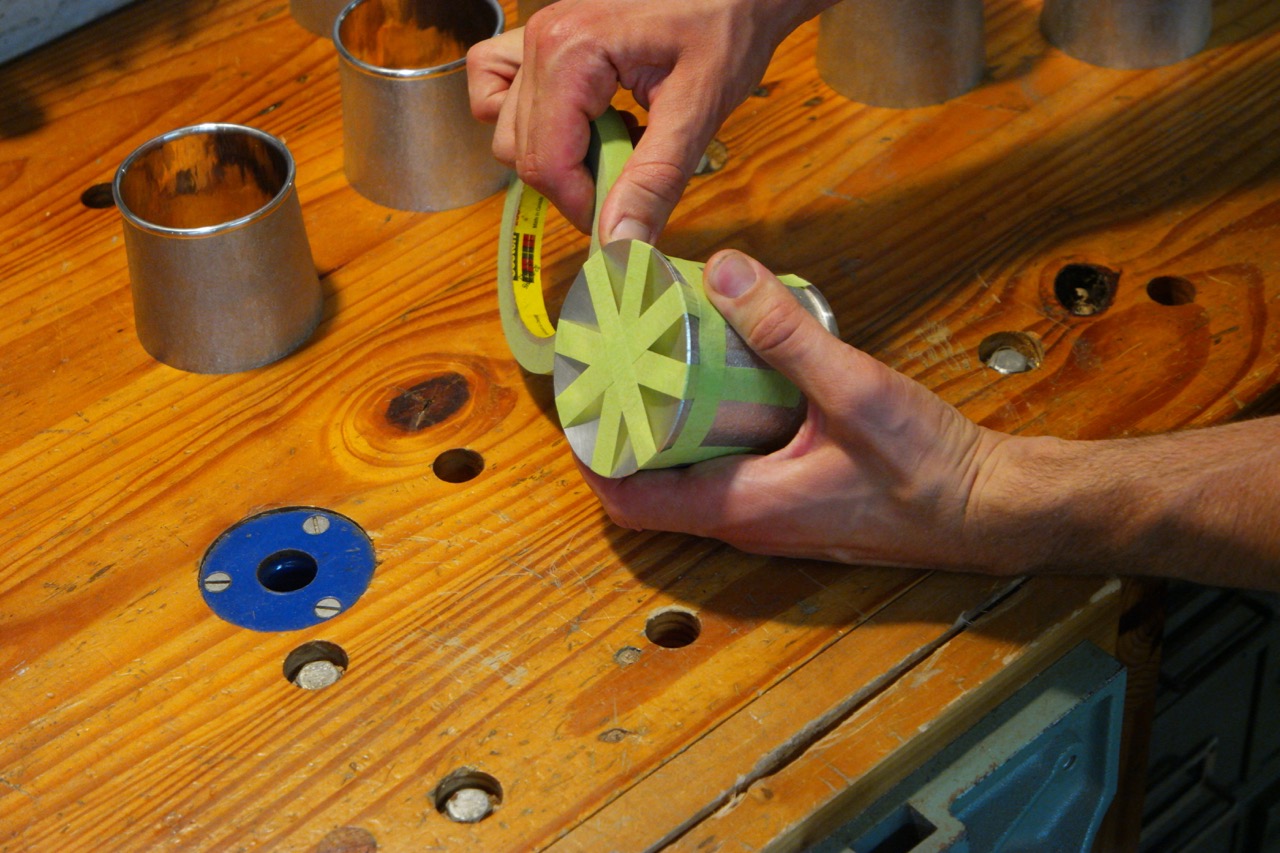

Here’s a run down of my process in pictures. This is intended as a show-and-tell more than a set of instructions, but if you are interested in pewter-smithing and have any questions please shoot me an email. Click the first image to pull up a slide show with descriptions of each step.